1050/1060/1070/1350 O temper Aluminum foil for transformer winding

- Specifications:

- Description:

- Quality standard of transformer aluminum foil:

- Application scope of aluminum foil:

- Paper can be interleaved

- Technical Specification:

- Feather:

- Packaging & Delivery:

- Please Contact Us

Specifications:

Name: Aluminum Coils For Dry Power Transformer Windings Brand Name: XIN CHENG

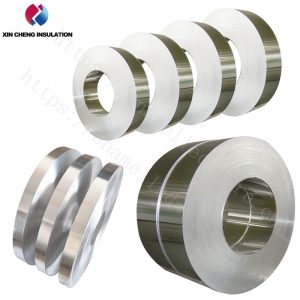

Temper: O Shape: roll/ strip

Application:Aluminum strip and aluminum foil for dry transformers and reactors, mainly used in large and medium-sized transformer manufacturing

Use: for transformer winding, reactors, mutual inductors and filters Place of Origin: China

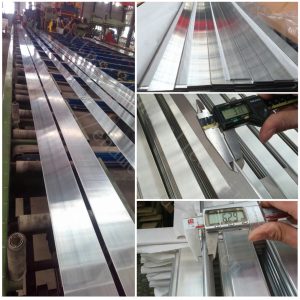

Edge: no burr or scratch /smooth Alloy Or Not: Non-Alloy

Edge treatment: Edge can be chamfered (round corner ) round edge or Pressing edge

Surface: smooth, clean, no oil stains, no waves, Free of black spot, line mark, creases, wrinkles, etc.

Tensile strength: 60-95N/mm2

Surface Protection: blue film covered or paper interleaved

Alloy: 1050 1060 1070 1350 aluminum foil for transformer winding Yield (≥ MPa): 0~560Mpa

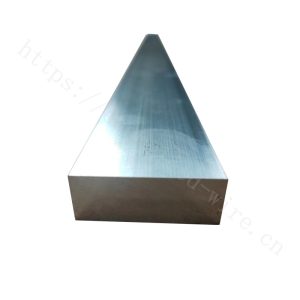

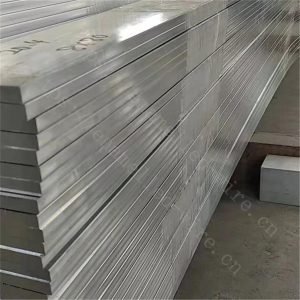

Thickness: 0.1mm~ 3.0mm Width: 15-2200mm

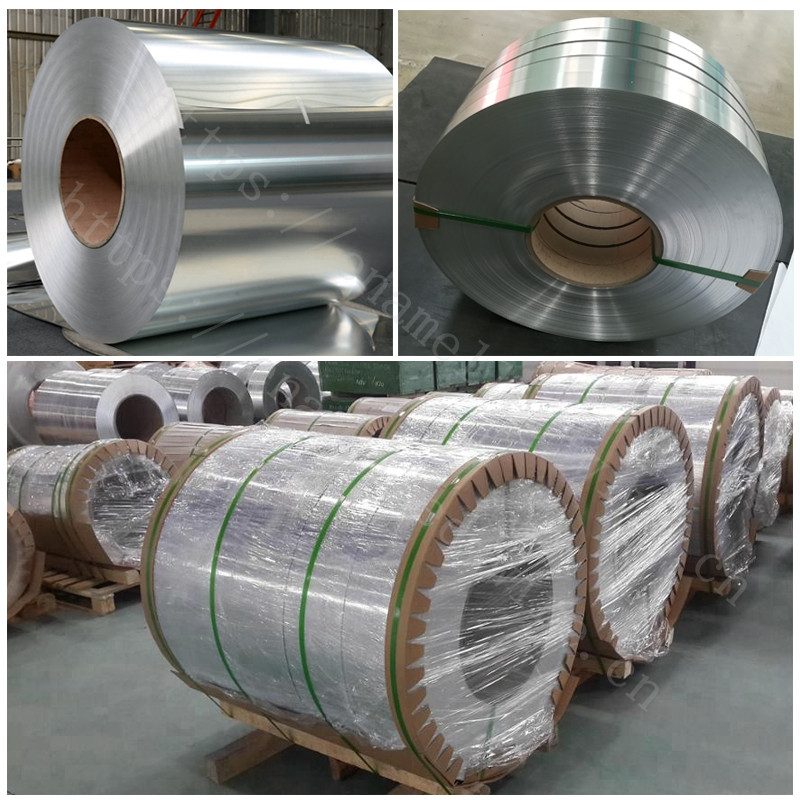

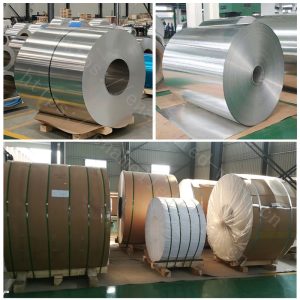

ID: 150mm,200mm,300mm,400mm and 500mm or Customized OD: MAX 1700MM

Color: Silver Aluminum Color Weldability: good

Density in 20 degree: 2.703kg/dm3 Elongation: (≥ %): 25%

Max. Resistance in 20 degree: ≤ 0.02825Ω Mm2/m Conductivity(20℃): ≥61.50 % IACS

Advantages: high conductivity, low side camber HS Code: 7606119900

Package: eye to sky and eye to wall both available Trade Terms: FOB, CIF, CNF, EXW

Certificate: CQC, RoHS, ISO9001,SGS Standard: GB/T3880-2006 GB/T3190-2008

Port:Shanghai port, Tianjin port, Qingdao port, Ningbo port, etc.

Additional Item: Customized service is available (Size, Alloy, Temper, Packing & Pallet Weight)

Description:

Winding material aluminum foil is widely used in transformers, reactors, mutual inductors and filters. It has good forming property, high corrosion resistance, good weldability and conductivity.

There is no burr on the edge of winding material aluminum foil. Surface atomization treatment makes the surface of winding material aluminum foil get to a brighter and cleaner level.

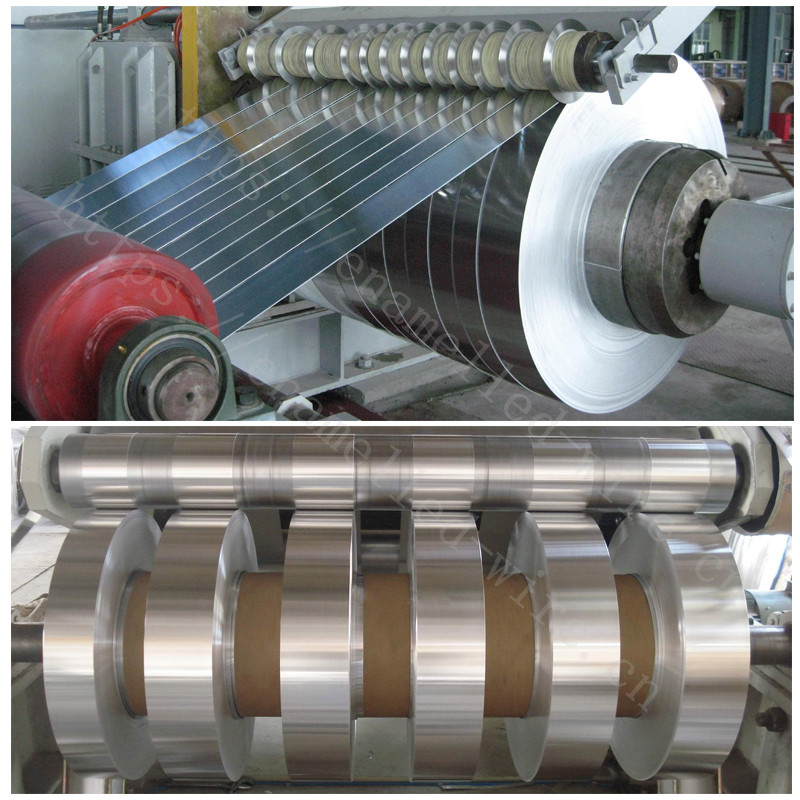

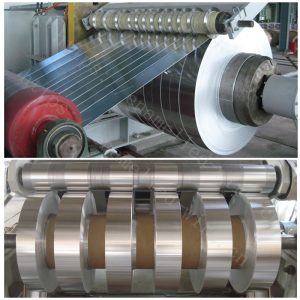

Winding material aluminum foil has always been to maintain industry leading position with the domestic leading technology. Rational design and renovation without changing the precision of the 1250 high speed slitting line make the height of burr less than 0.01 mm and the side camber lower than the standard of industry to enhance the commonality. Processing capacity and scope also increase accordingly.

Quality standard of transformer aluminum foil:

- The surface of aluminum foil is flat and clean;

- No corrosion marks, oil stains, wrinkles, slits, scratches, light and dark lines, cot prints, vibration marks, twill, etc;

- There are no bright spots, roller marks, grinding wheel marks and black lines on the surface of transformer aluminum foil;

- There is no yellow oil spot, oil sticking, blistering and tearing on the surface of aluminum foil.

Application scope of aluminum foil:

The typical application of aluminum foil/aluminum coil include: Cable/ Fiber optic cable/ Transformers/ Heater/ Building/ Aerospace/ Automobile industry/ Other fields

Aluminum foil for transformer is mainly used in large transformer, solar energy and power industry. Transformer aluminum foil is the main material to make transformer winding. The quality of aluminum foil directly affects the quality and application effect of transformer.

Transformers are designed and built with copper or aluminum windings. But transformers using aluminum foil winding have advantage of small size, light weight, good insulation properties, flame retardant, non-polluting, partial discharge, resistant to moisture, smooth and reliable operation, low noise, and low maintenance cost.

In dry type transformers, aluminum–aluminum windings have been commonly used nowday. Aluminum foil strip can replace copper conductors in distribution transformers. Aluminum foil and sheet in appropriate strip widths and lengths have widely replaced wire in electrical transformers.

Demand for aluminum foil using for oil transformer is new and will be more.

Transformer aluminum foil is mostly industrial pure aluminum, commonly used models are 1050 aluminum foil, 1060 Aluminum foil, 1070 aluminum foil, the thickness range is 0.1-3.0mm, the width is 20-1650 mm(our product range is 15-2200MM), with good conductivity and thermal conductivity, high plasticity, good corrosion resistance, and can withstand the stretching and bending of various pressures

0.2 thickness 1060 Al foil for low voltage transformer is widely used in low voltage transformers. 0.2 thickness 1060 Al foil for low voltage transformer has good forming property, high corrosion resistance, good weldability and conductivity.

There is no burr on the edge of 0.2 thickness 1060 Al foil for low voltage transformer. Surface atomization treatment makes 0.2 thickness 1060 Al foil for low voltage transformer surface get to a brighter and cleaner level.

0.2 thickness 1060 Al foil for low voltage transformer has always been to maintain industry leading position with the domestic leading technology. Rational design and renovation without changing the precision of the 1250 high speed slitting line make the height of burr less than 0.01 mm and the side camber lower than the standard of industry to enhance the commonality. Processing capacity and scope also increase accordingly.

Our company has a high quality source of raw materials. Customers are the first and high quality of products is our principle. We focus on the raw materials information and raw materials inspection to ensure the quality of the raw materials.

We are professional manufacturer of Aluminum Products. We can supply high Quality ALUMINUM FOILS,ALUMINUM STRIP,ALUMINUM SHEET and other ALUMINUM ALLOY. No scratches, Smooth edges.

ALUMINUM STRIP, Slitting is closely controlled to assure smooth, substantially burr-free edges and strip-size availabilities are in capacities exactly equivalent to those of standard copper wire sizes.

Our high conductivity roll type electrolytic aluminum strips used to manufacture the windings of electrical transformer, distribution transformer, cast resin transformer.

The strip conductor is of high conductivity annealed quality. Slitting is closely controlled to assure strip free of cracks, roughness, scaling, stretch marks.

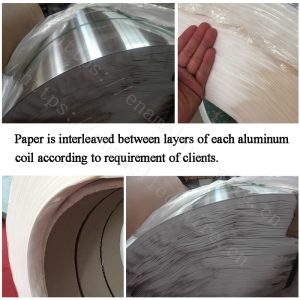

Paper can be interleaved

Paper is interleaved between layers of each aluminum coil according to requirement of clients.

Aluminum foil are free of dents, surface defects, waviness, scale, or any other imperfections which would cause problems in either the winding, performance, or reliability of a quality manufactured dry or wet transformer.

The surface and edges of the material is free of burrs and imperfections, flat with no raised edges and shipped in tightly wound rolls with proper edge register.

Technical Specification:

Technical Specification of Aluminum foil 1060-O:

- Product Range

Thickness: 0.1–3.0 mm

Wideness: 15—2200 mm

- Dimensions:

(1) Thickness Tolerance:In accordance with GBT3880-2006.

(2) Width Tolerance:In accordance with GBT3880-2006.

- Edge Deburring Range:

Thickness 0.1–0.85mm Pressing edge

Thickness 0.9—3.0 mm Pressing edge or round edge

- Protection:

Possibility for paper-interleaving and papercore.

Thickness: 0.3–4.4mm

Width: 200–2200mm

- Inside & Outside Diameter

| Thickness(mm) | Width(mm) | Internal Dia.(mm) | Protection | Outside Dia.(mm) | Comment |

| 0.1~0.4 | <200 | 150、300、400 | Interleave paper | 700~1700 | Allow cross, no adhesion to a broken end |

| ≥200 | 300、500 | ||||

| 0.4~1.5 | ≥200 | Interleave paper | |||

| <200 | 150、300、400 | ||||

| 1.5~3.0 | ≤200 | 300、400 | |||

| ≥200 | 500 | ||||

| Other dimensions upon request. | |||||

- Surface Finish:

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use.

Smooth, clean, be free of oil, stain, scratch, wave and corrosion, ready for paint, and lamination. No oil stains without oxidation,In accordance with GBT3880-2006.

The surface of the aluminum foil is uniform in color, clean and flat, without obvious roll marks, pits, pinholes, and corrosion marks;

The surface of the aluminum foil has no rolling defects such as creases, mottles, and bright lines;

The surface of the aluminum foil has no rolling defects Color difference;

No oil on the surface, no serious oil odor, no oil spots visible to the naked eye;

- Production standard:

Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM

Mechanical Property: GB/T 3880-2006, JIS, EN, ASTM

- Mechanical Properties:

| Aluminum Foil/Strip with Rounded Edges for Transformer Winding | ||||||||||||||

| Aluminum alloy | A1060/ A1050/ A1350 | Temper | O | |||||||||||

| Thickness(mm) | 0.2-0.3 | 0.4-0.8 | 1.0-2.0 | 2.0-3.0 | ||||||||||

| Thickness Tolerance(mm) | ±0.015 | ±0.02 | ±0.01 | ±0.06 | ||||||||||

| Width(mm) | 20-100 | 100-200 | 201-500 | 501-1300 | ||||||||||

| Width Tolerance(mm) | ±0.1 | ±0.2 | ±0.2 | ±1 | ||||||||||

| Mechanical property | ||||||||||||||

| U.S.T : 60-95N/mm 2 | Elongation:>25% | |||||||||||||

| Density in 20°C : 2.703kg/cm 3 | Max resistance in 20°C : ≤0.02825Ωmm 2 | |||||||||||||

| Chemical Composition % | ||||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | V | Ti | Al | ||||

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | – | – | 0.05 | – | 99.5 | ||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.03 | 0.05 | 0.05 | 0.03 | 99.6 | ||||

| 1100 | 0.95 Si+Fe | – | 0.05 – 0.20 | 0.05 | – | – | 0.1 | – | – | 99 | ||||

| 1350 | 0.1 | 0.4 | 0.05 | 0.01 | – | 0.01 | – | 0.05 | – | 99.5 | ||||

| Major Brand | A1060(O) A1050(O)A1070(O) | ||||||

| Thickness | 0.2-0.4 | 0.4-0.8 | 0.9-1.1 | 1.2-1.6 | 1.8-2.0 | ||

| tolerance | ±0.01 | ±0.015 | ±0.02 | ±0.025 | ±0.03 | ||

| Width | <100 | 100-200 | 201-500 | 501-1250 | >1250 | ||

| tolerance | ±0.1 | ±0.2 | ±0.2 | ±1 | ±2 | ||

| BURR AND COLLAPSE | |||||||

| The width of aluminum belt | burr’s height | collapsed side’s height | |||||

| <0.2 | 0.01 | ≥0.05-0.1 | |||||

| 0.2-1.0 | 0.015 | ||||||

| 1.1-1.5 | 0.02 | ||||||

| >1.6 | 0.03 | ||||||

| ALUMINUMSTRIP MECHANICAL PROPERTY | |||||||

| U.T.S: 60-95N/mm2 | Elongation: >25% | ||||||

| Density in 20 degree:2.703kg/dm3 | Max. resistance in 20 degree:≤0.02825Ωmm2/m | ||||||

- Material 1060-O, we also can supply 1070-O or 1350-O

Feather:

We produce high conductivity roll type electrolytic aluminum strips used to manufacture the windings of electrical transformer, distribution transformer, cast resin transformer.

The foil conductor is of high conductivity annealed quality.

Slitting is closely controlled to assure strip free of cracks, roughness, scaling, stretch marks.

Paper is interleaved between layers of each aluminum coil according to requirement of clients.

Each coil is tightly wound.

Foil is free of dents, surface defects, waviness, scale, or any other imperfections which would cause problems in either the winding, performance, or reliability of a quality manufactured dry or wet transformer.

The surface and edges of the foil is free of burrs and imperfections. The edges conform to a Round Edge.

steady and consistent quality, good product durability, high performance and cost ratio, professional team.

super thin, super extractive;

thin and light;

High strength;

high thermal conductivity

excellent silvery white luster, beautiful appearance.

No Burrs

Round / Pressing Edge, Edge can be chamfered (round corner ) round edge or Pressing edge

High Conductivity

High Purity

Totally Annealed

Excellent performance of anti-causticity

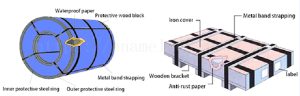

Packaging & Delivery:

Packaging Details: Fumigation-free of wood pallets, corrugated paper, paper angle protector, PVC film and desiccant for Al foil for low voltage transformer and interlayer paper, or according to customer’s requirement.

The packing can be eye to sky or eye to wall based on the customer’s requirement

Delivery Detail: 20 working days after 30% T/T payment received.

Please Contact Us

Miss: lydia

Mob: 86-13752439076 Fax: 86-22-60863016

WeChat :86-13752439076 WhatsApp: 86-13752439076